Location:

PMKI > Project

Management History > Henry L Gantt.

- Henry L. Gantt’s work and

contribution

to management

- Gantt’s books and publications

(original texts)

Other related sections of the PMKI:

- The history of Bar

Charts

- The origins of

modern project management

- The development of

general management theory

- The history of project

controls

Simple bar charts appear to have been in use in manufacturing plant's before Gantt was called in to help improve manufacturing control and productivity: “Many shops have a very nice schedule system; they plan their work beautifully—at least, it looks very pretty on paper; but they have no means of finding out whether those schedules are lived up to or not.” Gantt’s focus was on increased production, through the use of effective measurement and planning. The charts he used (there were many different types) were only a means to an end: “The man who undertakes to introduce scientific management and pins his faith to rules, and the use of forms and blanks, without thoroughly comprehending the principles upon which it is based, will fail. Forms and blanks are simply the means to an end. If the end is not kept clearly in mind, the use of these forms and blanks is apt to be detrimental rather than beneficial.”

The innovations introduced by Gantt in the early 1900s, that are still very much the focus of modern project management included team motivation, change management, and the effective use of control systems. Whilst the focus of his work was in manufacturing, with the advantage of repetition and standardization, many of his ideas and processes are still valuable in today’s projects. Henry Gantt’s standout contribution was his innovative approach to workforce management, today we would call this 'team' management; overlaid with a strong sense of industrial democracy. It was focused on the efficient utilization of labour and a fair division of the rewards from any improvement in productivity between the workers and the owners of the factories.

The starting point of Gantt’s work was the ideas of scientific management introduced by Frederic Taylor. The best way to understand a complex task is to break it down into its component parts, scientifically study and optimize each part, and then synthesize the optimum way to complete the work from the optimized parts. What made Gantt’s work uniquely valuable was the way this information was used to motivate workers. His method involved scientific investigation and careful standardization of the work into tasks. Once a task had been set, individual instruction was provided to each worker, and once they had learned to perform the task in the set time and to the required quality, a bonus was paid in addition to their daily wage. Gantt recognized incentives are a far more powerful motivator then penalties. He described his approach as a system of education for the workforce, with a bonus for those who learned! It proved highly effective generated sustained productivity improvements well in excess of 100%. His system also interconnected the reward paid to the supervisor with the rewards paid to the workers. The foreman received a bonus for each worker in his team that received a bonus, but the foreman’s bonus was doubled if all of the workers in his team achieved a bonus. This encouraged the foreman to work with and support the least effective members of ‘the team’ to bring everyone up to standard.

Importantly whenever a bonus was not earned, the cause

was investigated and the cause of the failure removed or

remedied, Gantt wanted everyone to make their bonus every

day! When this was achieved, the plant as a whole was

working to its optimum productivity and generating the

maximum profits; a win-win outcome. When introducing his

system to a new factory, Gantt recognized that a “system

of management requires all of its parts to work in

harmony if it is to be effective” and that “in

every workroom there is a fashion, a habit of work, and

every new worker follows that fashion, for it isn't

respectable not to.” Consequently, “the changing

of a system of management is a very serious matter and

cannot be done by a superintendent in his spare time.”

Gantt recognized the change needed to introduce a new

system requires a high degree of skill, takes time and

needs planning! The challenge is getting senior management

to actively support the change that brings better systems

into use to the benefit of the organization. Unfortunately

many of the problems and issues Gantt identified are still

present in many organizations and still prevent the

achievement of optimal production outcomes!

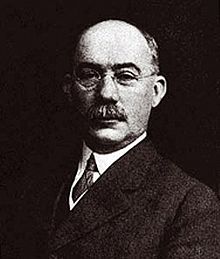

PP: Henry L. Gantt - A Retrospective view of his work. The importance of Henry Gantt to the development of project management and modern business management cannot be understated. This paper looks at the real contributions Henry Gantt made and consider them in the modern context, and traces his life’s work and contributions whilst debunking the myth that Henry Gantt developed bar charts. Henry Gantt deserves to be famous for the right reasons. A summary of this paper is in the conference PowerPoint presentation.

DP: Gantt charts

revisited: A critical analysis of its roots and

implications to the management of projects today*.

This academic paper explores the origins and use of the

Gantt Chart and reaches a number of conclusions similar to

the retrospective paper above (although the authors appear

unaware of the earlier uses of bar charts in the 18th and

19th centuries). The authors confirm Gantt's work focused

on repetitive factory operations and was developed in the

early twentieth century, at the heart of Scientific

Management; yet, the chart is used with very little

adaptation across a wide range of types of projects. In

this conceptual paper, the authors question its universal

and unreflective use.

*Joana Geraldi, Thomas Lechter, (2012),Gantt charts

revisited: A critical analysis of its roots and

implications to the management of projects today,

International Journal of Managing Projects in Business,

Vol. 5 Iss: 4 pp. 578 - 594

PP: Where did the Misuse of the names Gantt and PERT Originate? This article traces the rise in the misuse of the term 'Gantt Chart' associated with the incorrect designation of a Bar Chart in Microsoft Project as a ‘Gantt Chart’.

Blg: Henry Gantt vs Karol Adamiecki

Two adaptations of the bar chart were the Harmonogram, (or

Harmonygraph / Harmonograf) developed by Karol Adamiecki

in 1896 and the various Gantt Charts developed by Henry L.

Gantt from the early 1900s through to 1919. This post

looks at both the charts, and the management philosophy of

Adamiecki and Gantt and suggests one possible connection

between the work of the two management pioneers.

Henry

Gantt's books (available for download - large PDFs):

Henry

Gantt's books (available for download - large PDFs):

Work Wages & Profits 2nd Ed, 1919. (original Ed. 1913).

The Gantt chart a working tool of management (Wallace Clark, 1923).